.png)

About GenForce® | DFS:

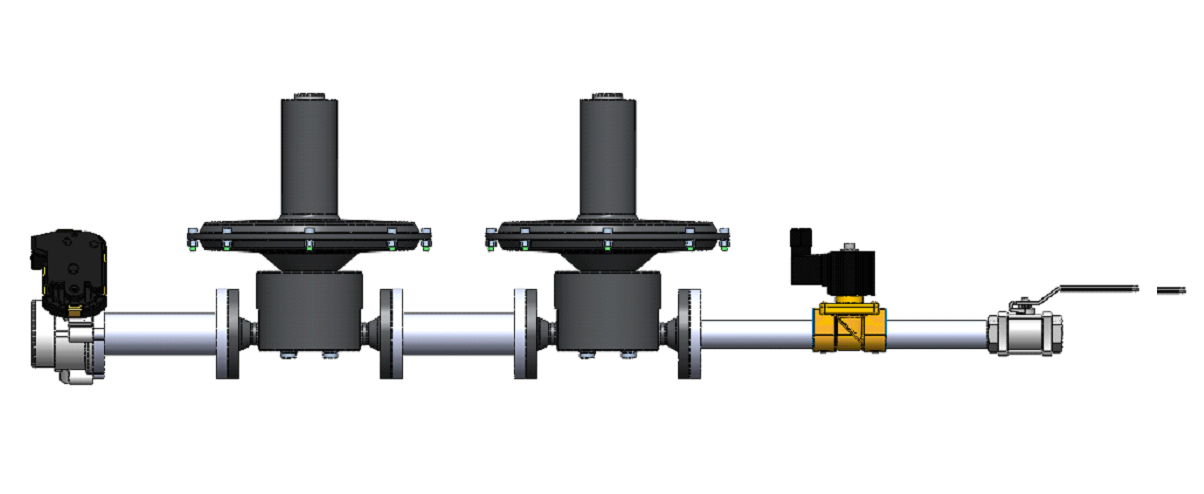

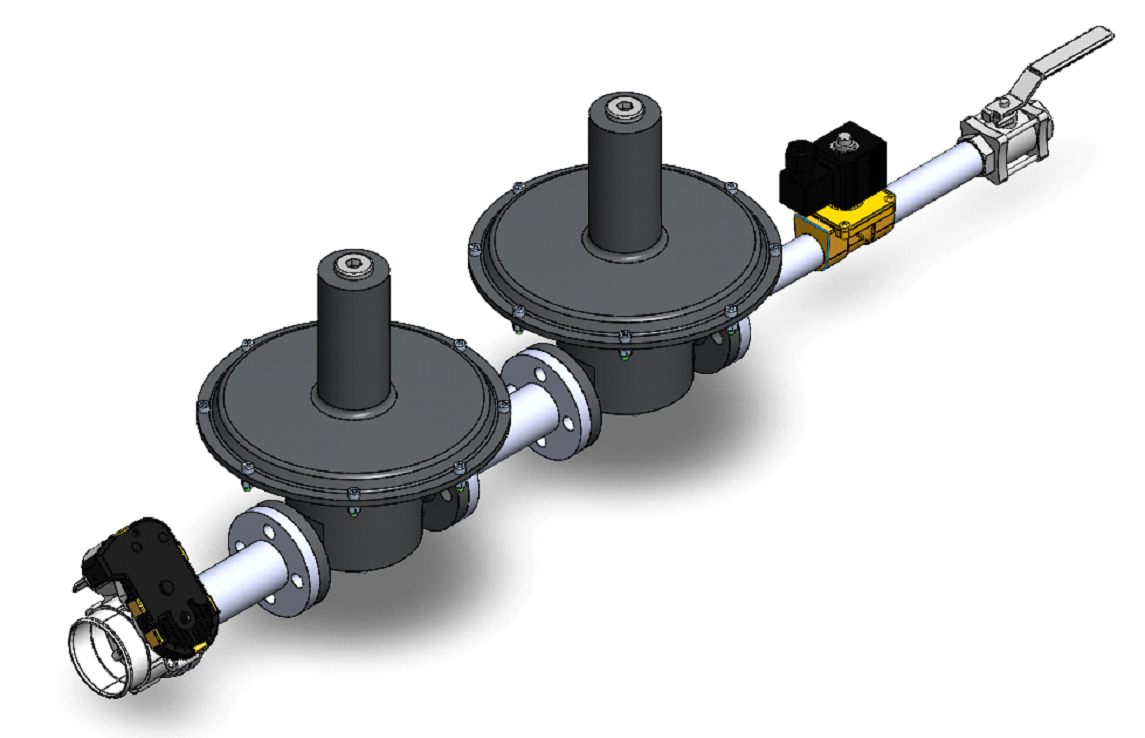

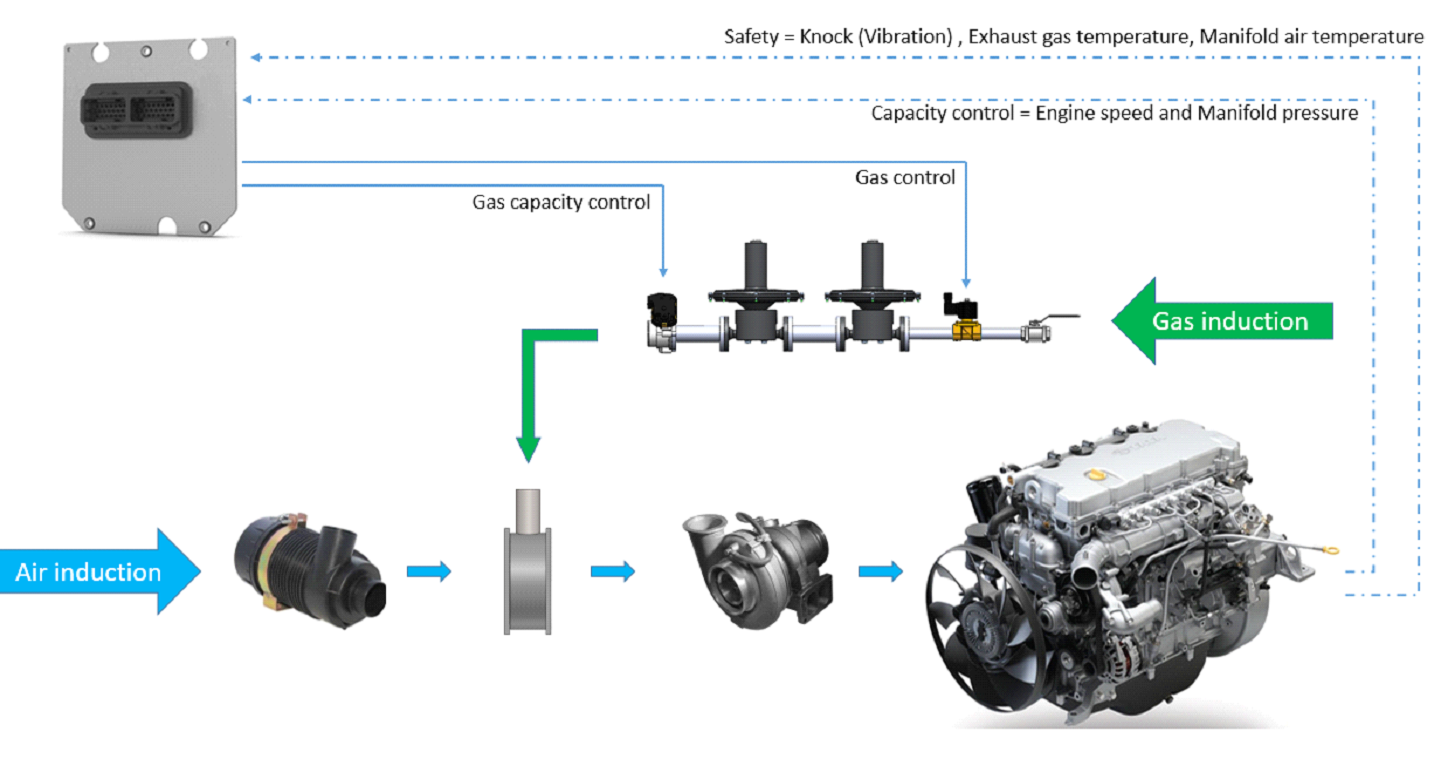

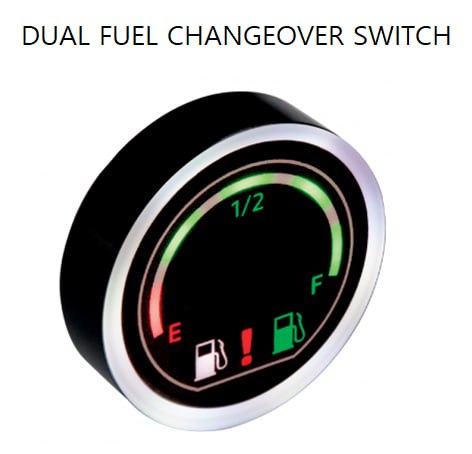

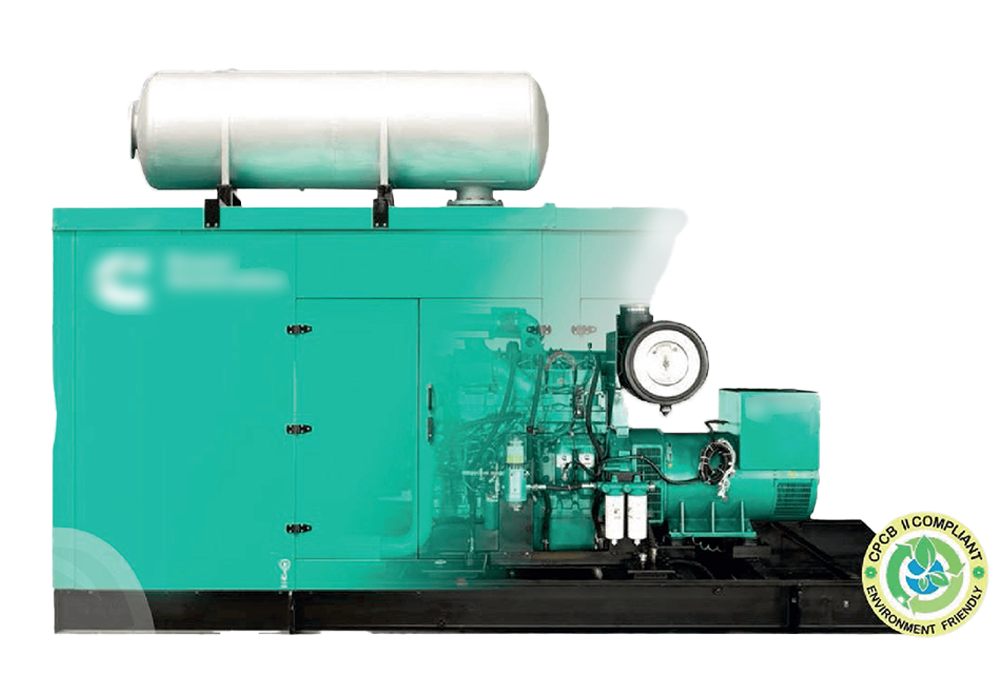

Dual Fuel system in generators will operate in the technology of simultaneous combustion of two fuels. Existing diesel injection considered as primary fuel, additional fuel such as gas (PNG / CNG / LPG) considered as secondary fuel system. In our case the primary fuel system is un disturbed to retain the same performance of existing generator.

GenForce DFS Technology:

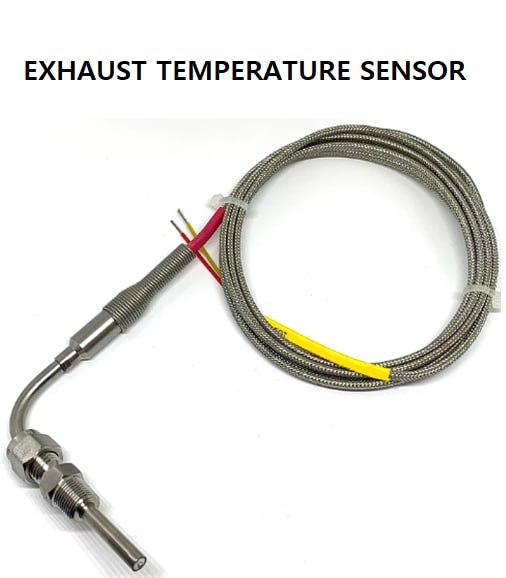

GenForce DFS System for generators works by starting on Diesel fuel and then adding PNG until the mixture offers maximum efficiency. The generator can switch seamlessly between diesel-only and dual fuel operations, prevent- ing unwanted disruptions and downtime. The generator can also resume Operating with only diesel if the gas supply is not available

Another key benefit of the Dual Fuel System is that it can keep the engine power levels steady while using gas mode within the "continuous and "prime" ratings of the engine. If the opera- tion exceeds the set power limit, the engine automatically switches to 100% diesel mode, so there is no need to lower the engine rating. For applications with large load variations, our system allows for changing the gas substitu- tion rate based on a fuel vs. load map.